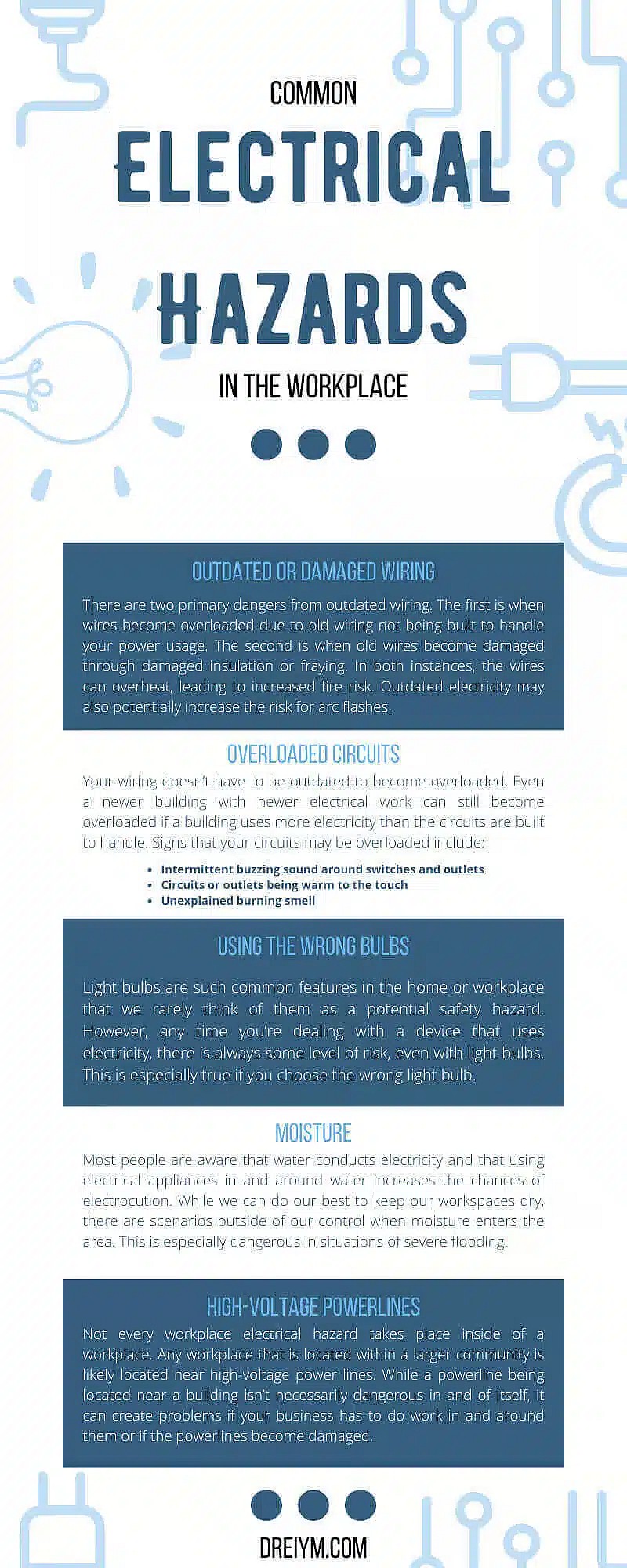

Common Electrical Hazards in the Workplace

Every career has its own unique hazards. Those working in the logging industry have to avoid injuries due to falls. Factory workers have to avoid accidents while working with heavy-duty machinery. Even those working in offices have to navigate health concerns from sedentary work or unergonomic workstations.

However, whether your workday finds you sitting at a desk with a laptop or at the base of a sycamore tree with a chain saw, there is one safety concern that is constant. It’s the risk of electrical-based safety concerns, such as electrocution or electrical fire. But knowing the common sources of electrical hazards in the workplace can help you take the necessary steps to protect those around you.

Outdated or Damaged Wiring

Those who live in older or historic homes know that old wiring can become problematic for day-to-day living, and the same is true for those who work in older buildings. But the biggest challenge isn’t the potential outages.

There are two primary dangers from outdated wiring. The first is when wires become overloaded due to old wiring not being built to handle your power usage. The second is when old wires become damaged through damaged insulation or fraying. In both instances, the wires can overheat, leading to increased fire risk. Outdated electricity may also potentially increase the risk for arc flashes.

Rewiring a building is a large task, especially for older buildings, and it’s a task that should be left to professionals. However, you can take steps to prepare for a professional’s arrival by taking inventory of your business’s electric usage.

Overloaded Circuits

Your wiring doesn’t have to be outdated to become overloaded. Even a newer building with newer electrical work can still become overloaded if a building uses more electricity than the circuits are built to handle. Signs that your circuits may be overloaded include:

- Intermittent buzzing sound around switches and outlets

- Circuits or outlets being warm to the touch

- Unexplained burning smell

- Dimming or flickering lights

- Electronics or tools running slowly or at half-power

Like outdated wiring, overloaded circuits can overheat and cause a fire. They may also increase the risk of electrocution simply by putting your hand near the outlets.

Knowing your circuit breaker is a key strategy for avoiding this common workplace electrical hazard. Knowing how much electricity the device can reasonably take will help you strategize what devices, tools, or appliances can and can’t be used in the workplace. Additionally, try to avoid plugging too many devices into the same outlet or power strip.

Using the Wrong Bulbs

Light bulbs are such common features in the home or workplace that we rarely think of them as a potential safety hazard. However, any time you’re dealing with a device that uses electricity, there is always some level of risk, even with light bulbs. This is especially true if you choose the wrong light bulb.

Every light bulb has an assigned wattage—the energy that it uses. And each light socket has a maximum wattage associated with it. Choosing a light bulb with a higher wattage than the socket creates a situation called “overlamping,” when the socket becomes overheated. This can increase the risk of fires, especially if you are placing the bulb in an enclosed light fixture. To avoid this, double-check the socket before installing or purchasing new bulbs.

Moisture

Most people are aware that water conducts electricity and that using electrical appliances in and around water increases the chances of electrocution. While we can do our best to keep our workspaces dry, there are scenarios outside of our control when moisture enters the area. This is especially dangerous in situations of severe flooding.

When a business’s building gets flooded, especially if it’s flooded in basements or other areas that contain electrical equipment, a person can become electrocuted simply by wading into the water. If a flood occurs, do not enter or have any of your employees enter a flooded space. Instead, contact a professional who is equipped to do so safely.

High-Voltage Powerlines

Not every workplace electrical hazard takes place inside of a workplace. Any workplace that is located within a larger community is likely located near high-voltage power lines. While a powerline being located near a building isn’t necessarily dangerous in and of itself, it can create problems if your business has to do work in and around them or if the powerlines become damaged.

When possible, it’s best practice to avoid close contact with powerlines, putting up barriers to keep employees from walking too close to them. However, this isn’t always possible for businesses that take you to sites that are located near lines. If you must work near powerlines, strive to take proper precautions, such as:

- Not using metal tools or ladders near lines

- Utilizing proper PPE

- Ceasing work in wet conditions

- Not using compromised tools

- Being wary of trees near powerlines since they conduct electricity

In some instances, you may be able to contact your local utility company in order to get power lines de-energized while your crew is working. But even if the lines have been de-energized, it’s essential for everyone working in the area to continue to act with caution, as if they were turned on.

Improper Usage of Heavy Equipment

Office buildings tend to be known for using the most electricity of any workplace due to the high volume of computer usage. However, industrial workplaces such as factories, warehouses, and construction sites are also known for high electrical usage, and where there is more electricity usage, there is more room for hazards.

For these businesses, most of these hazards stem from heavy equipment—specifically, not following proper protocols for heavy equipment usage. Those working around this kind of equipment should be supplied with proper PPE and trained in how to use systems such as lock-out tag-out when performing maintenance.

Faulty Grounding Equipment

Even if a facility seems to be safe from electrical problems, its employees can be at risk without realizing it if the facility isn’t practicing proper grounding techniques. Improperly installed grounding equipment can lead to an increased risk of fire or electrocution.

The signs of faulty or improperly installed grounding equipment are often similar to the signs associated with other electrical problems, such as dimming lights or electrical equipment not working. If you aren’t sure if your electrical problems are related to grounding, contact the electrical engineering experts at Dreiym Engineering. We can help you assess the risks at your workplace to keep you and your employees safe.