Dreiym Engineering PLLC offers a variety of corrosion engineering and corrosion protection services, including cathodic protection services. All of our corrosion engineers are National Association of Corrosion Engineers (NACE)-certified CP4 professionals. As such, you can rest assured that, when you contact Dreiym Engineering’s cathodic protection consultants, your current project is in the trusted hands of qualified and experienced professional engineers.

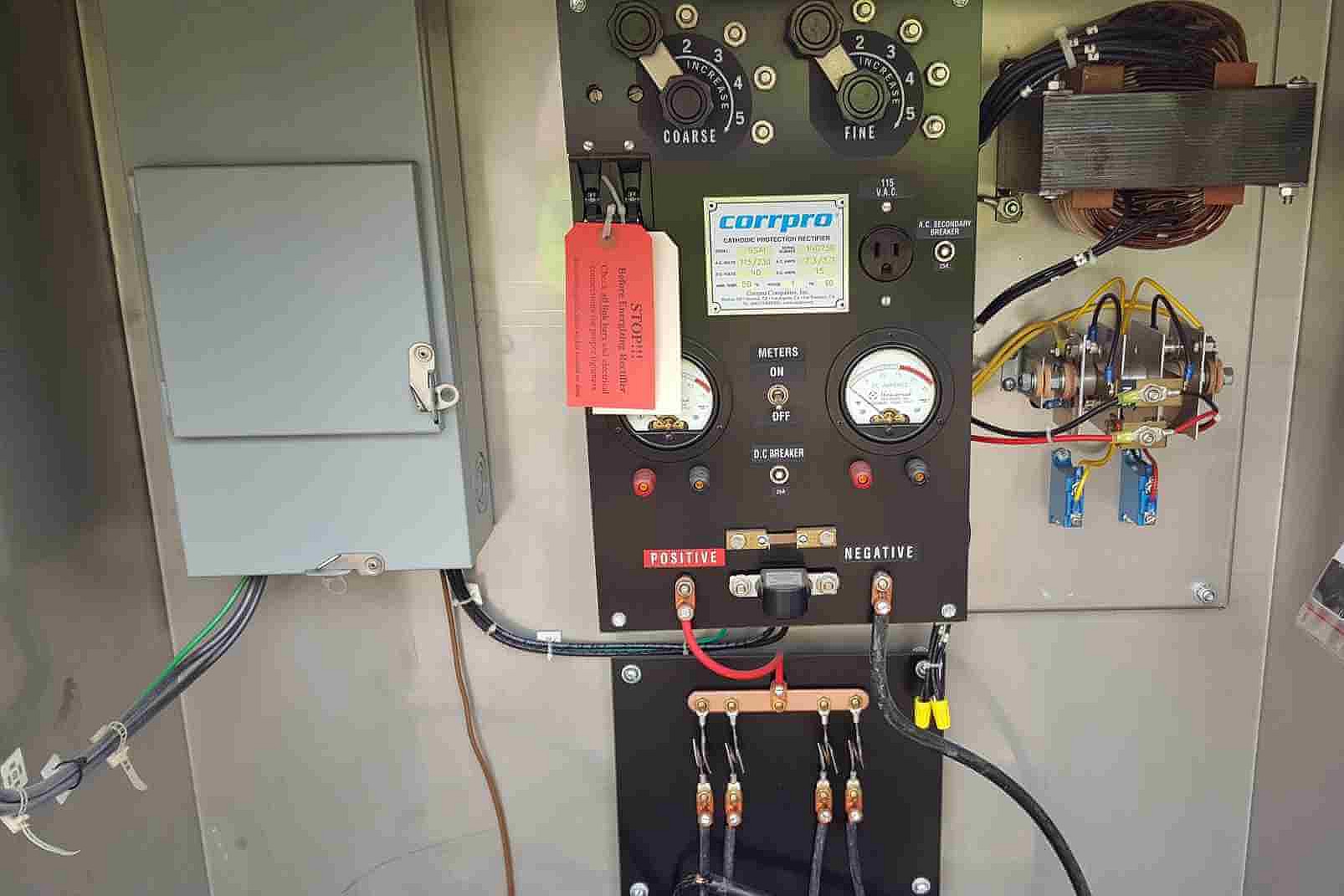

Dreiym provides exceptional design services for Cathodic Protection Systems, including both sacrificial and impressed current systems for use with underground pipelines, submarine pipelines, and above-ground and underground storage tanks.

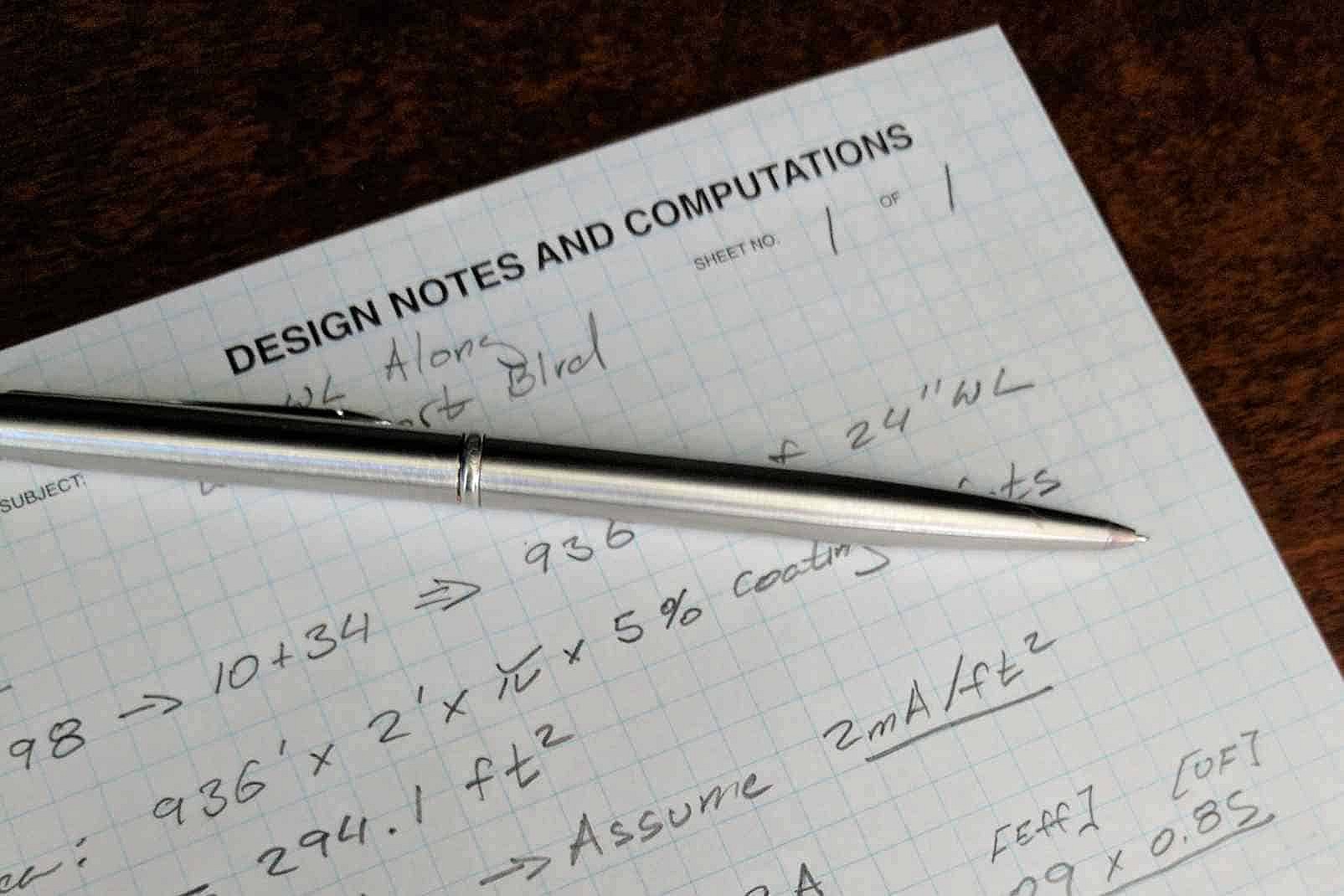

Previous projects include complete system design, construction oversight and commissioning tests. Designs are completed in accordance with the applicable industry standards and the National Associate of Corrosion Engineers (NACE) International best practices. We will provide you with detailed design specifications for the installation of sacrificial and impressed current systems. We can oversee installation and draw up the documentation needed to evaluate installation health, conduct quality assurance checks, and supervise the installation.

Our cathodic protection consultants are also equipped to carry out quality checks on existing corrosion protection systems to ensure everything is in working order. We can provide you with a detailed list of recommendations for any repairs, maintenance, or replacements needed to bring your pipeline or storage tanker up to code. This will ensure the problem is addressed before it turns into a more expensive issue that will cost you more in the long term.

We can produce designs and detail drawings covering:

- Deep Anode Groundbeds

- Conventional Groundbeds

- State-of-the-art Remote Monitoring

- Distributed Anode Systems

- Above-ground Storage Tank (AST) Corrosion Control

- Underground Storage Tank (UST) Corrosion Control

- Elevated Storage Tank Corrosion Control

- Plant Pipeline Network Cathodic Protection

- Marine Cathodic Protection

- DC Rail Corrosion Control & Interference

- Cathodic Protection Test Stations

- Corrosion Coupon & Probe Monitoring

- System Safety Grounding

- Interference Analysis & Mitigation

- AC Interference & Mitigation

- and More!

We also offer electrical load analyses. Corroded wires and other corroded components can cause systems to overload. If you suspect corroded components are reducing your systems’ efficiency, an electrical load analysis can confirm your suspicions. And if your suspicions are confirmed, we can provide the cathodic protection needed to stop corrosion in its tracks and keep your electrical loads balanced. Contact us today to learn about our corrosion control engineering and consulting services!